Our ability to create exceptional timepieces is thanks to the talented team of component production and watchmaking specialists that Romain has put together at Manufacture Romain Gauthier in Le Sentier, Switzerland.

Each member brings a unique savoir-faire to the creative process and each leaves their own signature on the finished timepiece.

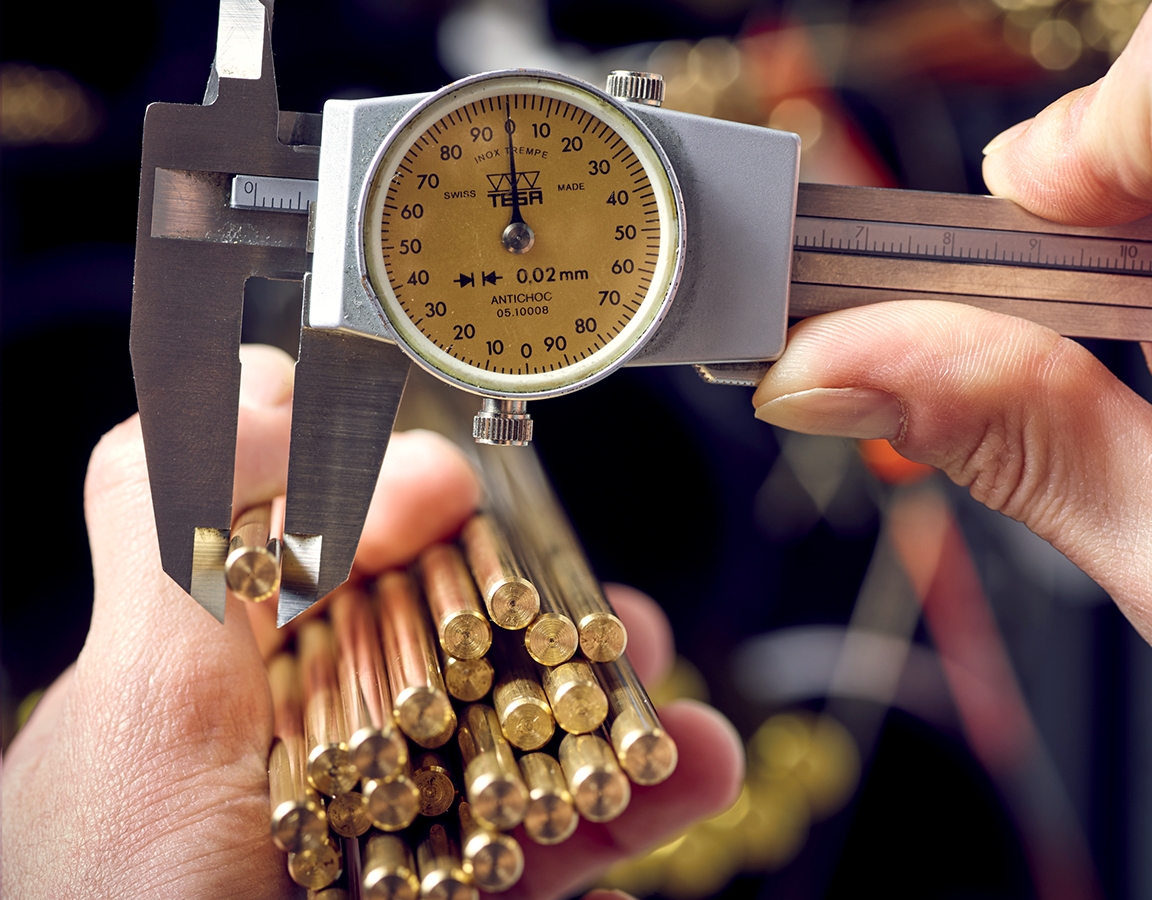

Skilful machining of components

Lathe operators machine components of the movement that Romain has designed, working classic and modern materials tolerances of +/- 2 microns. A micron is 1/50 of the diameter of a human hair.

Making components look good and last longer

Our production experts harden, polish and temper components to prolong their lifespan and make them gleam. They also burnish components to increase surface hardness for durability and increase smoothness for superior contact.

Decoration using hand-operated tools

Our decoration specialists embellish our movements with aesthetic finishes including spotting (perlage), snailing (colimaçonnage), circular graining (cerlage), hand-frosting (grainage) and Geneva waves (côtes de Genève).

Bevelling and polishing bridges by hand

The artisans of our anglage atelier devote hours to filing the angles between the flanks and surfaces of bridges into eye-catching bevels that are hand-polished using gentian wood that Romain collects from the local forest.

Time-honoured watchmaking techniques

Each movement is painstakingly assembled and regulated from A to Z by the same watchmaker. Our watchmakers master the full gamut of horological skills, including counting the balance spring and heat-bluing the hands.

Controlling quality and precision

Throughout, stringent quality control checks are performed during and between operations, and Romain inspects each finished timepiece under magnification.

Instilling beauty and soul

While this craftsmanship means quality is uncompromised and precision is impressive, it also imbues Romain Gauthier timepieces with a rare beauty and unique soul.